How can costs be saved in food logistics? Answer A: with the use of multi-chamber systems in the vehicles. Answer B: with the optimization of the processes before delivery, more precisely when picking in the depot. The solution lies in a combination of A and B! Intelligent route planning software optimally coordinates the processes in the warehouse and during transport so that perishable fresh produce reaches the customer as quickly and efficiently as possible.

Komplexe Anforderungen in der Lebensmittellogistik bewältigen

Ordered today - delivered tomorrow: In line with the challenges that the transport of frozen, chilled and fresh food poses to route planning, the fresh produce logistics are associated with a high level of complexity that starts with the ordering of the goods. Since the orders are released in a continuous process after the order, continuous picking in the warehouse is necessary. The warehouse employee compiles the ordered goods and brings them to the truck loading area - in other words, a gate where the tour usually leaves. Sounds straightforward, but only works theoretically. Because this is where the loading of multi-chamber vehicles - i.e. the optimal division of the required frozen, chilled and fresh capacities - comes into play, which becomes all the more complex in view of fluctuating orders. Rescheduling manually is a feat that those responsible cannot and do not want to do all the time.

Automatically calculate capacities for food logistics

Frozen - chilled - fresh: The size of these three units can be set variably in a multi-chamber vehicle. Depending on the customer's ordering behavior, a new decision is made every day whether, for example, twelve frozen and six fresh items are required on a tour or vice versa. And route planning takes on this calculation and adjustment task: A conventional solution works exclusively with static vehicle capacities; Intelligent route planning software, on the other hand, analyzes the orders and makes use of the fact that the individual chambers can be temperature-controlled as required. It is therefore clear in advance how the vehicle should be loaded. This enables customers to adapt their picking processes at an early stage.

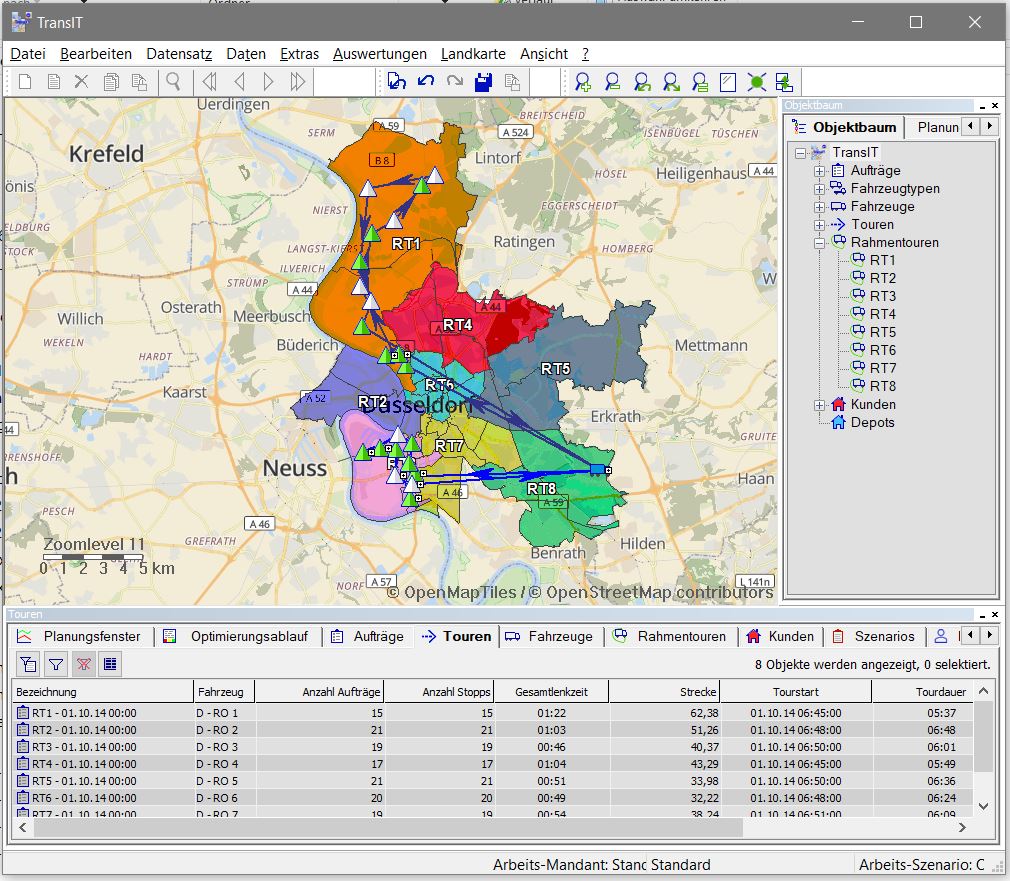

TransIT provides extensive digital support for temperature-controlled transports: the software has algorithms that can be used to optimally and individually configure the loading of the vehicle every day. Customer orders always form the basis for planning. In addition, TransIT identifies the number of trolleys or pallets to be delivered and the capacity of the variable filling chambers of the trucks, in which the delivery quantities in the various temperature ranges can change dynamically from day to day, but also between individual doors. The gts solution then decides how the compartments in the vehicle can best be rearranged and which goods are stowed in which location. Basically, the better the route planning, the lower the transport costs and the fewer manual corrections to the routes are necessary in day-to-day operations.

Optimum utilisation of vehicles for food logistics

For this, however, the framework tour planning must first be in place: In this case, this means both the assignment of customers to tours or vehicles and the assignment of these tours to gates or ramps of the warehouse on the basis of historical order data. The order picker knows the right gate for the respective orders and TransIT can adequately plan all goods the evening before. So that too many customers are not assigned to a tour and the driver can accommodate all goods, the planning of the framework tour is based on average order quantities. As a rule, the driver can stow and deliver all goods made available to him in the vehicle in this way. The result: a utilization of 80 to 90 or more percent. A consistently high utilization, but not an overload, speaks for the quality of the framework tour planning. In addition, it means that all tours are used as evenly as possible in terms of time and are optimally divided geographically. Nevertheless, there can be rescheduling in day-to-day operations. If a vehicle is overloaded or underloaded despite optimized framework tours, TransIT carries out this automatically with the help of intelligent algorithms - in other words, the software decides for each tour which orders are to be moved to other tours. The system generates repacking lists for this. The result: less chaos when repacking, minimal rescheduled tours and continued maximum efficiency!

Are you a fresh produce logistics specialist yourself? And your multi-chamber vehicles could be better utilized? Get in touch with us: Together we will work out a concept for the best possible way for your goods to reach the customer.

Here you can find our Success Stories .